Table of Contents

Innovative machinery is revolutionizing industries worldwide, offering increased efficiency, sustainability, and profitability, redefining traditional methods and shaping the future of industrial operations.

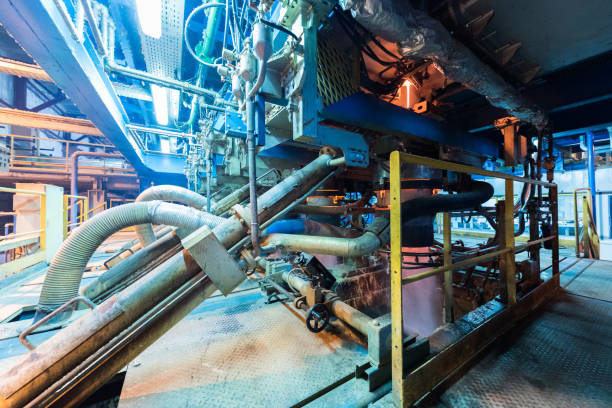

1. The Evolution of Industrial Machinery

Over the past century, the industrial landscape has evolved significantly, from steam-powered systems to sophisticated machinery. With advancements in technology, machines have become more efficient and specialized. Today, artificial intelligence and the Internet of Things are integral to machinery, enabling autonomous communication and process optimization. This evolution aims to meet global market demands while addressing environmental and economic challenges.

2. The Impact of Automation and Robotics

Automation and robotics have significantly transformed industrial operations, offering unprecedented precision, speed, and adaptability. These technologies minimize human error, reduce operational costs, and mitigate safety risks in hazardous environments. In manufacturing, robots handle repetitive tasks with high accuracy, allowing human workers to focus on more strategic roles. Industries ranging from automotive to electronics leverage automation to streamline production lines, enhance quality control, and ensure consistency. The integration of AI-driven robots further bolsters efficiency, as these machines learn from data patterns to improve performance over time. Consequently, automation and robotics stand as pillars of modern industry, driving continuous improvement and innovation.

3. Sustainable Machinery Solutions

As global environmental concerns intensify, the push for sustainability in industrial processes has never been more pertinent. Modern machinery increasingly incorporates eco-friendly technologies designed to minimize waste, conserve energy, and reduce emissions. For instance, electric-powered equipment and machines utilizing renewable energy sources are becoming more prevalent. Additionally, advanced materials and design innovations enable the creation of durable, long-lasting machines that enhance resource efficiency. Predictive maintenance technologies also play a crucial role by ensuring machines operate at optimal efficiency, thereby reducing energy consumption and extending their lifespan. These sustainable solutions not only protect the environment but also offer economic benefits through cost savings and regulatory compliance.

4. The Rise of Smart Factories

Smart factories represent the pinnacle of industrial innovation, integrating cutting-edge technologies to create highly intelligent and responsive manufacturing environments. IoT devices, AI, and big data analytics converge to facilitate real-time monitoring and decision-making. In these factories, machines communicate and collaborate seamlessly, adjusting operations to maximize efficiency and adapt to changing demands. Predictive analytics help anticipate maintenance needs, minimizing downtime and extending equipment life. Moreover, smart factories enhance supply chain management by providing transparency and improving coordination. This interconnectedness not only boosts productivity but also allows for greater customization and flexibility in production, meeting the needs of a dynamic market.

5. The Role of 3D Printing in Manufacturing

3D printing, or additive manufacturing, has revolutionized traditional manufacturing processes by enabling the On-demand production of complex parts and products. This technology builds items layer by layer from digital models, offering unparalleled design freedom and reducing material waste. Manufacturers can swiftly prototype new designs, speeding up the development cycle and bringing products to market faster. 3D printing also supports customization and small-batch production, catering to specific customer requirements without the need for expensive tooling. Industries such as aerospace, healthcare, and automotive are capitalizing on this technology to create lightweight, durable components, thus demonstrating its vast potential to reshape manufacturing workflows.

6. Future Trends in Industrial Machinery

Looking ahead, several trends are poised to further revolutionize industrial machinery. The integration of AI and machine learning will enable more autonomous and adaptive systems, capable of self-optimization and real-time problem-solving. Advanced materials, such as smart composites and nanomaterials, will lead to the production of lighter, stronger, and more efficient machinery. Additionally, blockchain technology is set to enhance supply chain security and transparency, ensuring the authenticity and traceability of products. As industries continue to embrace these innovations, the focus will also shift towards human-machine collaboration, fostering environments where machines augment human capabilities, driving productivity, and innovation to new heights.